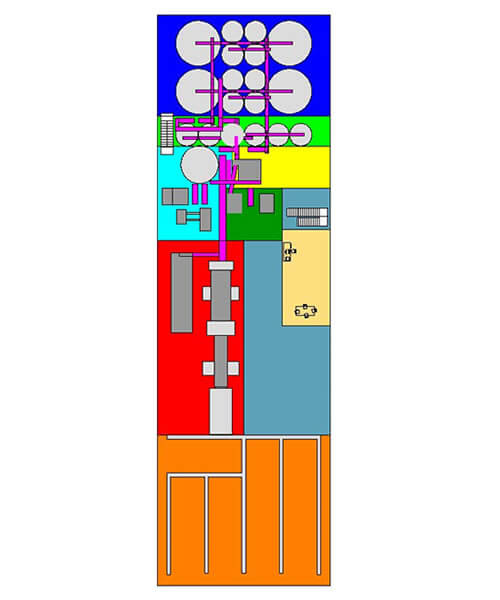

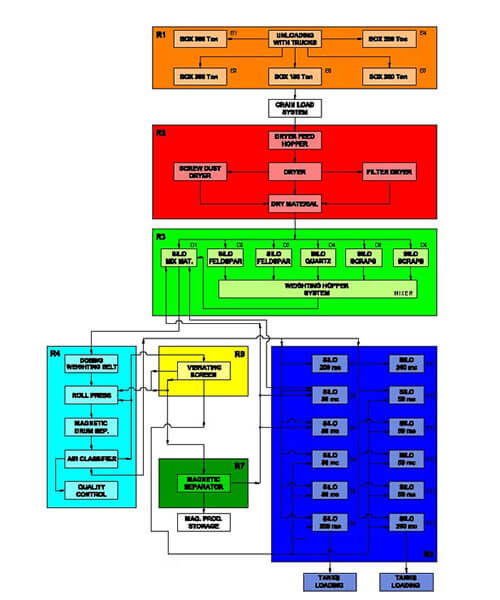

Production Process

The production process can be described by the attached technological diagram. Transport of raw material from storage boxes (5 boxes available) to a dryer feeder is carried out by hydraulic grabs mounted on a bridge crane. From this feeder, the material is fed into a rotary drum dryer. The dried raw materials leave the dryer and go to an elevator that transports them to storage silos, where they await further processing.

After the drying process, the individual raw materials, depending on the formula required, are weighed into a mixing feeder, which is equipped with a strain-gauge weighing system. The raw material mixture (up to 5 different raw materials can be processed) is temporarily stored in the silo, where it is prepared for milling. The fine milling is carried out using a roller mill. The required grain size is set on an air classifier that separates the finely milled finished product from the coarse grains, which return to the mill. The product is stored in shipping silos at the output of the air classifier. There are 4 silos with a capacity of 200 tons and 8 silos with a capacity of 50 tons. Finished products are delivered to customers in silo-trucks, bulk bags, or paper bags.